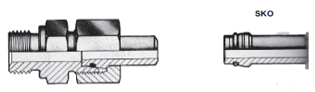

COUPLINGS WITH WELDING BOSS

Weding bosses SKO are constructed in such a way that they can be employed in connection with normal -bodies and - nuts of steel of the series S A weding boss with a fitted O-ring is placed in the 24 cone of the body.

Function:When the nut is tightened up the sealing is effected by the packing collar on the welding boss in the stop of the body and additionally by the O-ring at the cone wall.

Execution:Part No. : SKO

The respective O-rings are deliverable with the welding bosses separately.

Welding boss : Material - steel fusion weldable.

Surface - bright oiled.

O- rings : Perbunan (standard)

Viton (on demand)

Pressures: On corresponding selection of the pipes the nominal pressures indicated for the couplings can be applied. A safety factor of least 4 x is given. Under normal working conditions and termpratures up to 1200 C the working pressure can be equal to the nominal pressure. When O-rings of Perbunan are empoyed the admissible temperature is + 900 C.

It is assumed that the pipes and eqipments will be clamped in position in such a way that the

couplings will be free from any additional stresses, loads and tensions.

Special prospectus No. 33 on demand.

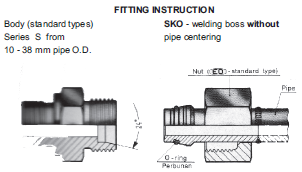

COUPLINGS WITH WELDING BOSS

1. Cut pipe square, debur, 300 chamfer (V-seam).

2. Push nut onto welding boss as shown.

3. Weld welding boss SKO with pipe in accordance with the general wleding directions.

4. Clean weld inside and outside.

5. Fit on O-ring. It has to be observed that the O-ring does not twist. Boss, nut, and cone

have to be clean.

6. Boss, cone, and threas have to be oiled before the fitting.

7. Tighten the nut firmly (with spanner 1/4 turn approx.).

8. Attention has to be paid that the pipe with the boss welded on is connected with body

straight and free of tension.

Special prospectus No. 33 on demand.